Topcon Supports Improvement Works in Large UK Shopping Park

This article was originally published inGeomatics World.

Situated on the southern edge of Leicester, Fosse Shopping Park is one of Britain’s biggest out-of-town shopping parks, attracting thousands of visitors each year. As part of a £155 million extension to the Fosse Shopping Park, McDermotts Building & Civil Engineering – a Chartered Institute of Building accredited construction firm – was appointed to complete the groundworks for the car park at the site, in preparation for a new surface to be laid. To prepare the land for the multi-million-pound works,McDermottsturned toTopcon Positioningto provide a solution with significant time-saving benefits.

“We have an ongoing partnership with Topcon and have been using its machine control technology for a number of years now,” explains Gavin Taylor, senior site engineer at McDermotts. “For the Fosse Shopping Park project in particular, we really saw the benefits of using the technology for positioning the dozers and digging out the foundations, and cut and fill when we were preparing the land for resurfacing.”

Decision-making based on highly detailed information

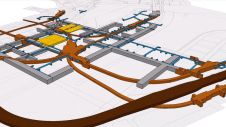

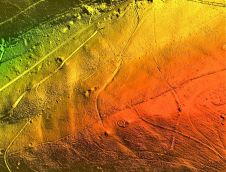

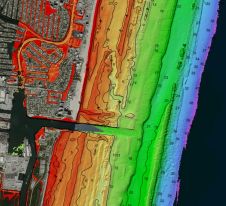

Topcon 3D machine control systems use GNSS data and 3D models to accurately deliver earthworks. Satellite positioning data communicates with a predetermined 3D model to give operators and engineers an accurate view of the machine’s current position compared to the desired result. This means decisions can be made based on highly detailed information, rather than on human judgement and traditional methods – both of which are less accurate compared to machine control systems, and can have a detrimental impact on surveying and materials cost.

“If we were to have completed these works using traditional methods, it would have taken us a lot longer,” continued Taylor. “As well as saving us time and money in terms of man hours on site, there was also an added element of safety. By using the machine control technology in conjunction with 3D modelling software, we were able to show the operators where the live surfaces were, so they knew to avoid them where possible, reducing safety risks on site.”

Some machine control platforms also provide material control capabilities, acting as a productivity tool for users and reducing the amount of material waste on projects. Simplifying grading, mass haul, and compaction enables operators to focus on material and site safety.

Remote access

Topcon’s 3D machine control platform in particular usesSiteLink 3D, an innovative platform that provides remote access and support to every machine connected to the system – including file transfers, messaging, reporting and analytics. This means any potential machine downtime is dramatically reduced as issues can be resolved in real time without the need for on-site technical support. Instead, engineers can troubleshoot operator queries remotely and ensure work continues with minimal delay.

Gavin Taylor concluded: “The machine control system from Topcon is absolutely brilliant, especially for this type of project. In fact, we’ve been able to save hours of time on the Fosse Shopping Park site, as well as increasing safety for our team and reducing the amount of material waste.”

Make your inbox more interesting.Add some geo.

Keep abreast of news, developments and technological advancement in the geomatics industry.

Sign up for free