Valuable Lessons for Survey Management

Currently, I am the survey manager of an 11.5-mile-long metro rail extension project (Dulles Metrorail Project) that includes 8.5 miles of at-grade track ballast walls, five at-grade bridges, three miles of elevated guide way, two half-mile-long tunnels and five stations. The project required the simultaneous development of a large survey staff and integration of multiple advanced survey technologies. Two systems-level ‘lessons learned' for survey management are discussed here.

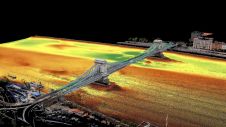

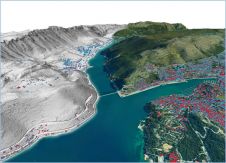

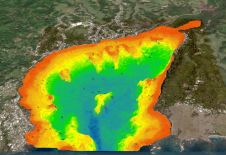

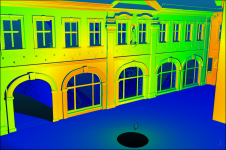

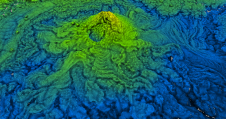

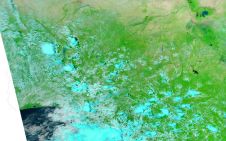

The survey technologies that were deployed and integrated into production operations are mobile laser scanning, static laser scanning, aerial mapping, secure network 2-way communication GPS and robotic instrument machine control, a central RTK GPS base station transmitting corrections over the secure network, Virtual Reference System GPS to complement the RTK system, complete reliance on free station survey control along the entire route, automated robotic instrument road-surface monitoring, laptop with wireless internet connection for field crews, solar-powered machine control GPS radio repeaters, web-enabled reporting of monitoring-data analysis for support of excavation and mining operations, track sled for rail as-builts and alignment verification, web-enabled GIS survey-work request system with orthophoto-image map base, precision-GPS GIS handheld data-collector unit and a central survey-data networked storage infrastructure.

The first lesson learned was that considerable effort and a significant amount of human resources are required to carry out large-scale integration of advanced survey-sensor raw data and data-processing results. This integration was a difficult undertaking, given the current state of data format standardisation within the industry. This needs to be a major focus area for improvement by the survey/geomatics industry. The current systems-integration costs are too high for all but the largest organisations to justify. There are exceptional benefits in productivity that can be experienced at all levels of production effort or organisational size, once such integrated systems of advanced survey sensors are in place. On this project, the survey systems integration was accomplished through a very high level of support from and cooperative effort by a large team comprising the project surveyors, the project and corporate information technology groups and the vendor technology experts (ESRI, Bentley, Leica USA, Riegl USA and Trimble).

The second lesson learned was that there is still a substantial knowledge gap between surveyors using integrated systems of advanced digital survey technologies and the project/construction managers they support and report to. This gap can be the source of communication breakdowns between the management and survey groups. There is a very real need for surveyors to provide education programmes for management and field engineers that will assist them in understanding modern survey technologies and work processes so that they can leverage survey expertise to increase project efficiency and productivity.

Make your inbox more interesting.Add some geo.

Keep abreast of news, developments and technological advancement in the geomatics industry.

Sign up for free