重新铺面银石的竞赛

使用高精度地理空间技术创建“终极赛车电路”

This article was originally published inGeomatics World。

Lead contractor Tarmac, along with its industry leading road planing business, NRP, racetrack specialist Dromo and project partner Topcon Positioning Group, combined expertise with innovative surveying and measuring technology to ensure a smooth result at the UK’s premier racetrack.

The Silverstone racetrack in Northamptonshire, England, has been a cornerstone of British motor racing for many years, having first hosted the British Grand Prix in 1948 and holding the title as its sole home since 1987. It was also the venue for the very first British motorcycle Grand Prix in 1977 and has retained the annual race for almost a decade.

如此古老的历史在该行业最有影响力的名字中获得了高度赞扬。在西尔弗斯通(Silverstone)最近获得英国大奖赛五年后,五届世界冠军刘易斯·汉密尔顿(Lewis Hamilton)称为Silverstone”the ultimate race circuit”,说,如果一级方程式赛将失去银石,“它将失去很多本质”。

值得一等surfa一流的电路ce, and in the lead-up to the hotly anticipated 2019 Grand Prix and MotoGP races, it was time for Silverstone to be resurfaced for the smoothest ride possible. There needed to be no bumps whatsoever and no opportunity for standing water, which can lead to dangerous aquaplaning. However, with only a couple of weeks to completely replace the track’s surface, it was clear that if the team were to get past the finish line on time, they would need to use the very latest paving technology.

Revving up

An expert team led by lead contractor Tarmac and Italian racetrack specialist Dromo was appointed to deliver the complex resurfacing project. Tarmac’s industry-leading road planing business, NRP, took the lead on the milling project, working with Topcon Positioning Group for its advancedSmoothRidemachine control technology and to ensure that there would be, quite literally, no bumps along the road. Not only that, but the team needed to alter the entire camber of the 5,500m-long circuit to optimise water run-off.

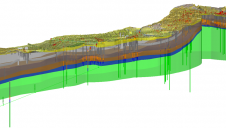

While the SmoothRide 3D analysis hadn’t previously been used on a racetrack, Tarmac, NRP and Dromo recognised the potential of the precision technology which had proven itself on highways and airport runways. It was to be the first use of the technology in the UK. Discussing the nature of racetracks, Sjoerd Stoové, 3D paving specialist at Topcon Positioning Group, said: “Racetracks are completely different from other roads – it’s very specialist work. This is mainly because on a normal road there are separate lanes, but on a racetrack the ideal racking line changes constantly from left to right. With Silverstone, there also needed to be two ‘crowns’ in the road, which were not always in the same spot, and there were very tight corners requiring quick camber changes over short distances.” However, the team were up for the challenge and set about bringing the new track to life.

而不是简单地取代顶层,track required a complete redesign. Stoové explained: “If you only take off the top layer and replace it, you are essentially just replicating the existing situation. We needed to create an entirely new surface not only to eradicate any risk of bumps, but also so we could shape a new camber that would make sure all water runs off to avoid aquaplaning.”

塑造光滑的表面

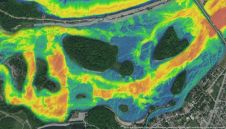

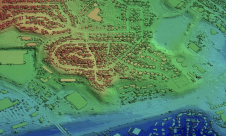

The project team first carried out a scan of the existing surface to precisely identify where any bumps were and where standing water might be likely. This scan data was then converted into a 3D digital terrain model (DTM) using Topcon’s Magnet Collage software, with the model being used to inform the new design.

决定将铣床用于塑造新轨道,因为它们可以使表面极高地水平,这意味着可以在恒定层厚度中进行铺路。这不仅具有用于材料的放置,滚动和压实的优点,而且还具有表面的实际寿命。

Sjoerd Stoové added: “The difference between the existing surface and the new design resulted in an average milling depth of 70mm over the whole racetrack. However, the problem with averages is that in some places you need to mill more, where in others you need to mill far less, or even not at all. Traditionally, a surveyor would need to spend days on the track to stake out all the milling depths and the crew on the machine then need to manually make sure those numbers are adhered to.”

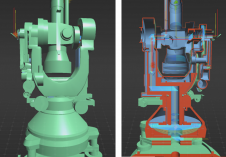

TopCon的RD-MC机器控制系统都避免了所有这些。首先,Magnet Officeand 3D Office were used to create the files needed for machine control from the design. The system was then able to use GNSS positioning to accurately calculate the difference between the existing surface and the new design at any given position, and therefore determine the desired milling depths.

机器上的传感器 - 在这种情况下,使用了两台Wirtgen W210FI机器 - 用于查明两侧的铣削桶的当前深度,然后根据所需的深度和实际深度,告诉机器,这些机器被告知将鼓移动或向上移动鼓或下。Sjoerd Stoové said: “This way, the new design is executed to millimetre accuracy, leaving the surface both extremely smooth and a perfect cross section.”

87,000平方米轨道的铣削只花了三天零两晚,并留下了一个无缝,平滑的子基础,可以完美地反映了3D设计,实现了使用传统方法几乎不可能的质量水平。还不需要测量师在沥青上绘制深度数量或创建汇总的线条,以节省调查工作的天数。而且,由于铣削的表面是如此准确,因此柏油碎石能够精确计算使用其最先进的BPO沥青管理系统铺路时所需的材料量。

Paul Fleetham, managing director of Tarmac’s Construction business, said: “Our approach to delivering this prestigious project blended the expertise of our teams with the latest innovations in digital construction technology.

“We wanted to ensure the new surface gives drivers the confidence to immediately attack the circuit’s iconic high-speed corners from their very first laps. Utilising cutting-edge precision systems like SmoothRide in partnership with Topcon helped us to achieve this goal.”

在终点线上

Unsurprisingly, it took a huge amount of preparation, dedication and collaboration to achieve a flawless finish on one of the most famous racetracks in the world. Working with Tarmac, NRP and Dromo to process the design data and create the required files for the machine control, including formulating a new workflow for milling, Topcon’s professional services team was able to integrate cutting-edge technology to maximum effect – all of which resulted in one of the smoothest milled surfaces ever to be seen on a racetrack.

Stuart Pringle, managing director of Silverstone Circuits Ltd, said: “Silverstone has always been a world class circuit, but thanks to the efforts of Topcon and Tarmac, the newly laid surface is truly world beating. I don’t believe there is a smoother finish on any race track anywhere in the world and that is thanks to the ground breaking technology Topcon brought to the project.”

要了解有关TopCon的机器控制技术的更多信息,see here。