GNSS和Heavy Equipment

远程信息处理和机器控制的财务益处

重型设备代表了建筑和农业等行业公司的主要资本成本。188asia备用网址近年来,全球导航卫星系统(GNSS)技术使用了美国全球定位系统和俄罗斯Glonass卫星系统星座的信号,已用于提高车队效率。许多公司可188asia备用网址能会犹豫投资于该技术,因为管理层没有意识到其利益。这种犹豫只有在当前的全球经济低迷期间增加了。但是,最近有证据表明GNSS技术可能对公司利润产生可衡量的影响。

Equipment telematics, the wireless exchange of electronic information for fleet monitoring, provides managers with powerful analytical tools to improve security, maintenance, utilisation, job costing and productivity.

Equipment Telematics

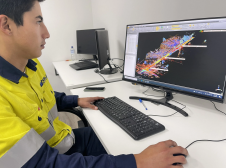

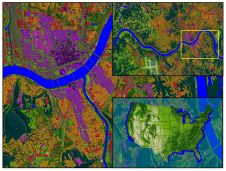

远程信息处理系统检测机器的操作并无线将数据传达给基于Web的网络进行实时监视;该数据还可以通过软件进行汇编,以进行周期性的深入分析(图1和2)。

These systems can detect when a dozer is idling or running at a higher number of revolutions per minute (RPM) while moving dirt, indicating, for example, how productive the machine is. Excessive idling time can also translate into a low ratio of fuel consumption to actual productive work. Total engine run time, or high-RPM operation, can be compiled and notifications set up at management-defined intervals to indicate the need for preventative maintenance, not just on the engine but on components and items such as hydraulic fluid. Machine servicing thus occurs at the best intervals, optimising the company's equipment and labour assets.

GNSS

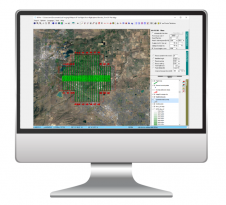

Using GNSS these systems can also detect where a vehicle is. Such positioning data can be useful for alerting management of equipment theft, the location of a lost machine or unauthorised use. In addition to tracking vehicles, these systems can be used to establish geo-fences

(Figure 3) and alert management via text message or email when a machine has gone beyond a boundary, helping management to minimise insurance costs.

Profitability Factors

远程信息处理最近已被证明会对两个因素产生积极影响,特别是对盈利能力产生重大影响。第一个是利用。管理层可以生成范围内的报道,例如,上周少于三个小时,在不到三个小时的时间内操作了多少次反铲。TopCon报告说,一位客户通过远程信息处理确定,它以每月约6,900欧元的费用租用两台机器,而无需一旦操作机器。与运营商培训机会相比,与生产时间呈现管理的分析相比,对生产时间进行了管理。可以说,用远程信息处理分析机器生产率的最有用的功能是,它为更准确的项目估算提供了机会,该估计设定了速率,可以恢复设备资本成本,同时保持整体项目利润率。

第二个因素涉及燃料成本。在过去几年中,这些成本构成了越来越多的运营成本。根据Topcon的说法Lambrecht Construction是一家大型美国挖掘和分级承包商,运营约五百台建筑机器和Tierra系统,仅通过使用远程信息处理来监视整个机队的发动机空转时间,每年将其燃油成本降低了数千美元。

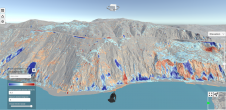

Machine Control

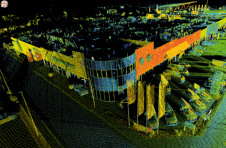

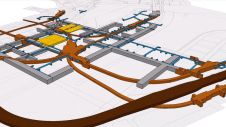

No technology has had a greater impact on excavation and grading work in the past few years than GNSS machine control. Still, it is estimated that less than 10% of the world's heavy equipment has been outfitted for machine-control operation. These systems use a GNSS antenna and receiver box mounted on a machine such as a dozer, grader or excavator. Satellites send positioning data to another antenna/receiver combination at a stationary base-station. Positioning data is also sent to the machine. Some contractors subscribe to a cellular network that provides positioning corrections using cellular technology, replacing a base-station and eliminating setup time for the latter. The stationary base and machine work together provide real-time kinetic (RTK) position information, revealing the machine's three-dimensional location on the site. Software compares the machine's position to the design grade, built from site plans, at a given location. The control box updates positioning data and sends signals to the hydraulic valves. Other sensors inform the control box of certain machine conditions; for example, a dozer is equipped with a slope (tilt) sensor on the blade to measure the cross-slope of the cutting edge. ‘Indicate systems' like Topcon's 3-D systems provide visual guidance for machine operators, who manually control the machine to cut or fill to the desired grade (Figure 4). In a fully automatic system, the blade is automatically positioned for elevation and slope.

四个节省

A major indicator of the financial benefit of any capital investment is ‘payback', or how long it takes to generate enough profit to equal the investment cost. Beyond this point the investment should only increase overall company profit. Although the savings vary according to differences between machines, workers and jobsites, the contractor can determine payback on machine-control technology by focusing on four areas of savings provided.

生产:当推土机需要更少的通行证才能使网站纳入规格之内时,这可能会导致项目完成速度更快,并且项目所有者的施工成本更低。操作员可以自信地削减或填充,并避免返工。节省时间还可以节省材料,人工和燃料。机器控制方面的最新进展正在进一步增加生产节省。TOPCON 3D-MC2系统使用惯性传感器提供刀片位置读数每秒高达一百次,大约比常规GNSS增加了大约五倍,从而使其他系统的生产率是其他系统的两倍,而无需使用评级的生产率是生产率的四倍。机器控制。TopCon毫米GPS+系统结合了激光和GNSS,使其适合精确的精细分级。

材料:分级规范可以节省material costs. The contractor uses less soil, base material and asphalt or concrete when machine control gets the grade closer to specification than conventional grading methods. The machine-control technology provider's analysis determined that grading 0.006 metre of EUR13-per-metric-ton material closer to specification through the use of the 3D-MC2 system resulted in a savings of about EUR1,870 per kilometre.

Labour: machine-control technology can drastically reduce the need for grade checking, either by the contractor's own personnel or by third-party services. This can save several thousand dollars in construction costs. Most contractors have established hourly rates for equipment plus labour. The contractor should determine what his hourly rate will be for a GNSS rover and operator and compare the cost with that of a surveying crew. The machine-control technology provider's cost analysis determined that reducing the distance between fine-grading stakes by half and the number of stakes per station by two-thirds, possible through the use of machine control, reduced the staking cost from about EUR3,300 to about EUR560 per mile.

燃料:当今每个地球运营的盈利能力的最大影响之一是燃料成本。在有或没有机器控制的情况下,记录机器每小时的燃油成本,也许是确定技术影响的最佳方法。

Calculating Payback

The contractor must also incorporate the cost of a machine-control system when estimating a project. A fully automatic system costs more than an indicate system. To determine the cost of operating any GNSS-enabled piece of heavy equipment, a simple calculation based on percentage of investment will suffice.

Payback periods vary greatly with the business skill of the contractor and the scale of projects. It is not uncommon for contractors to report that the cost of technology was recovered from savings realised on a single project. One machine-control technology provider conducted an analysis of reductions in site-work time and the corresponding savings that machine control can provide. According to the analysis, reducing the number of grader passes necessary to get to grade with a conventional system saved more than EUR12,000 on one site-work project and allowed a payback of the investment cost in just days (see Table 1).

通过机器控制储蓄:网站工作 |

|||

Production Savings |

Material Savings |

Staking Savings |

|

Length (metres): 300 |

Project size in square metres: 30,000 |

Project size in square metres: 30,000 |

Total Savings: €12,631 (1.9 days) |

Width (metres): 100 |

Thickness of material saved: 0.005 metre |

测量师数量:2 |

系统成本:62,500欧元 |

Number of passes to get to grade: 8 |

Cost per metric ton*: €12.85 |

Rate per hour: €104 |

System payback: 9.4 days |

Average crew cost per day: €2,430 |

总材料节省:€3,624 |

平方米每八小时的日期固定:10,000 |

|

Crew Cost for project: €6,075 |

Number of lifts requiring staking: 2 |

||

Number of days to grade project: 2.5 |

Total staking cost: €9,984 |

||

通过机器控制,通过以下方式减少了通行证数:2 |

With machine control, staking reduced by 75% |

||

提高生产率:25% |

节省存放成本:7,488欧元 |

||

Production Savings: €1,519 (in 1.9 days) |

|||

*(基于材料重量为1,880公斤的计算) |

|||

Competitive Contractor

Many contractors stay competitive by using the profit generated from the increased productivity as a buffer against inflationary costs. The true advantage of reducing costs makes it possible for small operators to compete at the bid table with larger companies that may be shying away from advanced technology.

使您的收件箱更有趣。Add some geo.

Keep abreast of news, developments and technological advancement in the geomatics industry.

Sign up for free