Crane Camera: Maximizing Space in a Constricted Area

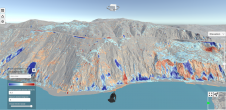

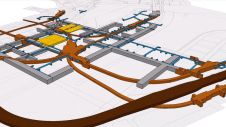

Planning and monitoring construction projects in tight urban areas is a challenge. That’s why The Beck Group relies on the Crane Camera. When a new dual-branded Hilton hotel was planned in Denver, USA, The Beck Group was commissioned to complete the architecture and the construction. Located downtown in a congested urban area, the 22-storey hotel posed significant construction challenges.

The limited space and the central location required extensive planning and reporting. For this, the team from The Beck Group decided to rely on aerial imagery to monitor the project and verify its progress. But instead of drones, which are typically used on their construction projects, the team counted on thePix4D Crane Camera solution.

Overcoming construction challenges

Building in a tight urban space

Situated on a narrow plot on the corner of two busy streets, the hotel’s location added complexity to the project.

Due to the lack of space, the team had to coordinate material deliveries efficiently and minimize overlapping deliveries which would lead to traffic congestion and the incapability to unload, requiring rescheduling and risking the delay of the entire project. Missing space also meant The Beck Group had to take full advantage of every available square foot, and store materials on top of the ongoing building.

Coordinating the deliveries required continuous collaboration with the suppliers and within the team as well as constant site progress tracking to avoid any mistakes and keep the traffic flowing during the day, and get the hotel built on time.

Concrete slab verification

Concrete pouring is a critical phase in the construction of a building and any mistake, even a little one, can literally cast in stone. “Any error with elements that go into a concrete slab can cause increased costs or project delays,” says Grant Hagen, VDC manager at The Beck Group, forcing the team to carefully verify their correct installation before pouring.

Once concrete is poured, all elements are covered: the only way for the team to locate and verify the elements is to drill the concrete. However, the process is complex, time-consuming, and many things can go wrong when drilling concrete.

贝克团队并没有花时间和金钱来补救错误,而是尽一切努力阻止他们。

The solution: aerial mapping without a drone

“无人机的绝佳选择!”

The solution the Beck team was searching for had to fulfill a number of requirements:

- Track the progress of the jobsite to avoid any mistakes that could cause traffic problems and slow down the project

- Aid deliveries planning, facilitate the collaboration and the communication within the team, and with all suppliers

- Verify the slab installation to minimize the risk of errors

Already seeing the value of drone mapping for construction, the team worked with drones at first. However, after a few flights they realized that UAVs were not the best solution for this particular downtown construction project.

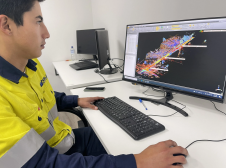

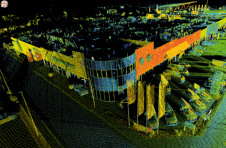

“I know the benefits of drones and drone mapping but I thought that drones were not the safest solution on this project - with urban environment and the downtown congestion. So, we chose the Pix4D Crane Camera, the safest solution we found so far for capturing aerial imagery to be turned into 2D and 3D. It’s definitely a great alternative to drones for construction projects,” explains Hagen.

该团队将Pix4D的起重机摄像头安装在单塔起重机上。起重机摄像机没有在棘手的城市环境中定期飞行无人机,而是自动工作,可以定期更新而无需进一步干预。

The results: automated construction site monitoring

用于更好计划和改进协作的数据,而无需离开办公室

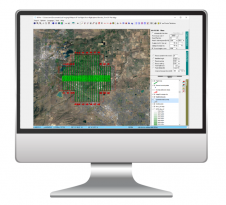

Meetings to track the site progress were a weekly routine for the Beck team. The Crane Camera data allowed the team to regularly share the status of the project with all the stakeholders, without leaving the office. The team was able to save time and resources they would typically spend to go on the jobsite to check the status.

"We used the data to check the site progress and to show it during our meetings with different subcontractors”, comments Hagen. “Being able to present the slab installations and the daily progress of the site without physically being out on site was very helpful for us. The Crane Camera gave us full site awareness.”

有效的混凝土板验证

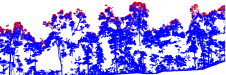

To control the key elements installed in each concrete slab, the team was able to compare the installed sleeve locations on the delivered orthomosaics, with the planned sleeve locations on the drawings.

“Verifying the concrete slab elements has always been a recurring problem. Traditionally, this would require a manual process with a human behind - either flying a drone, or walking out on the slab. With the Crane Camera we were finally able to document it very effectively and daily via an autonomous workflow, with a click of a button and no people involved: this was very efficient and saved us a lot of time,” says Hagen.

视觉记录以防止争议

正如哈根(Hagen)指出的那样:“有时候,直到将来报告问题之前,可能不会立即看到像起重机相机这样的工具的价值。”如果存在与平板安装有关的任何争议,团队有信心他们可以随时检查图像文档并回答潜在问题。

With the whole construction documented and stored online, the Beck team can go back in time and check what happened, even after the project has been completed.

完全自主的解决方案

“I believe the biggest benefit of the Crane Camera is that it is a fully autonomous solution. It doesn’t require any human interaction, other than to consume the information. It’s really helpful, especially for people like us that traditionally have a lot of things on our plates,” says Hagen.

Watch this story as a webinar

Grant Hagen discusses how The Beck Group were using the Crane Camera on a daily basis.Watch the webinar here.

本文的原始版本出现在pix4d.com.

使您的收件箱更有趣。Add some geo.

Keep abreast of news, developments and technological advancement in the geomatics industry.

Sign up for free